For our customer Sensorfact we developed a product for online flow measurement.

A proof of concept was delivered as start. Requirements for the final product were minimal assembly time, high quality pcb connections and easy install, all within their stated budget. From there we designed and sourced the parts for the final product. Manufacturing and testing is outsourced to one of our partners at request of the customer.

Used expertise

PCB design, Electronics, Sourcing, Prototype assembly, Sensors

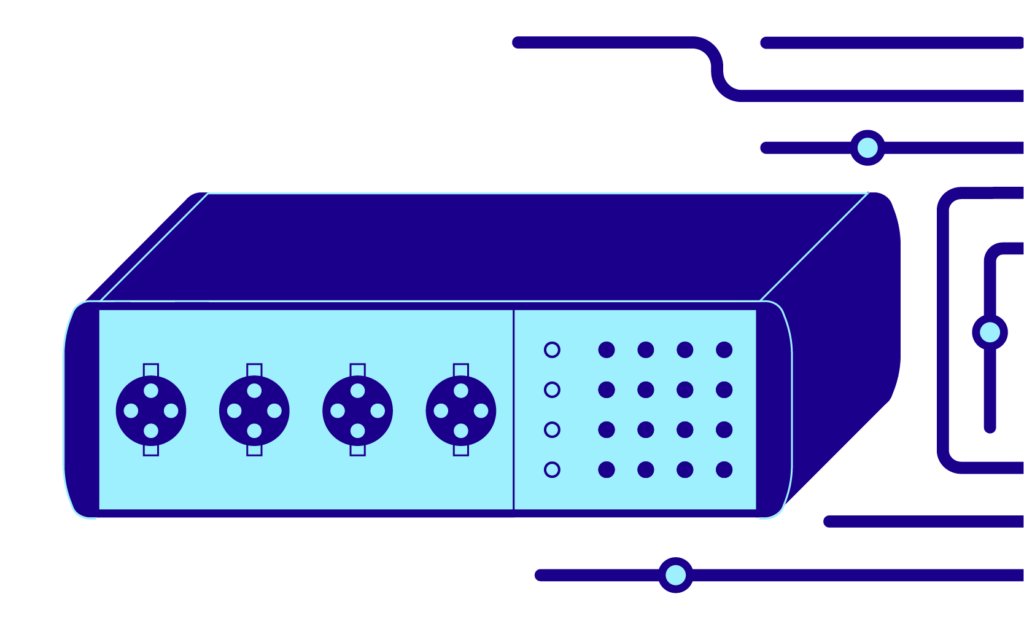

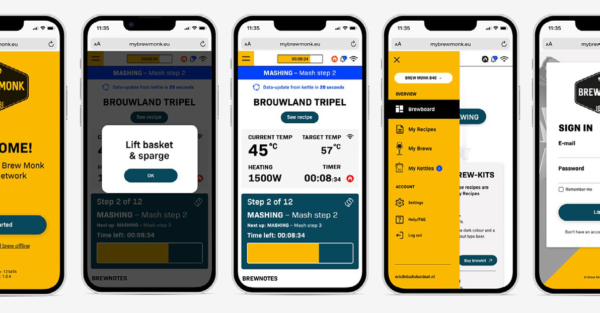

Brew Monk™

Brew Monk™ is a brand owned by Brouwland, the biggest online brewing components and ingredient supplier in Europe. The Brew Monk™ brand consists of brewer hardware of good quality at an affordable price.

Together with the Brewbrain team Brouwland developed a new series of all-in one brewing kettles, connected to the Brew Monk platform by WiFi. The goal is to assist and guide the brewer to the best brewing experience possible.

The platform offers a wide range of possibilities to store your brewing data and make your brewday easier.

The brewboard gives you an overview of your current brewing session and shows you the progress of your brewday. To store all your favourite recipes a library is designed. Furthermore it is possible to design your own recipes which you can synchronise to your kettle.

Next to that, the Brew Monk™ kettle has a very easy to use, intuitive display that allows you to smoothly control your brewing session. Actions and alerts are represented here when input form the user is needed.

All together a next level brewing experience. Join the future of brewing!

Used expertise

User interface design, Kettle display firmware, PCB design, Measurement and Control firmware, manufacturing, sourcing, front-end software, back-end software

Hurricane

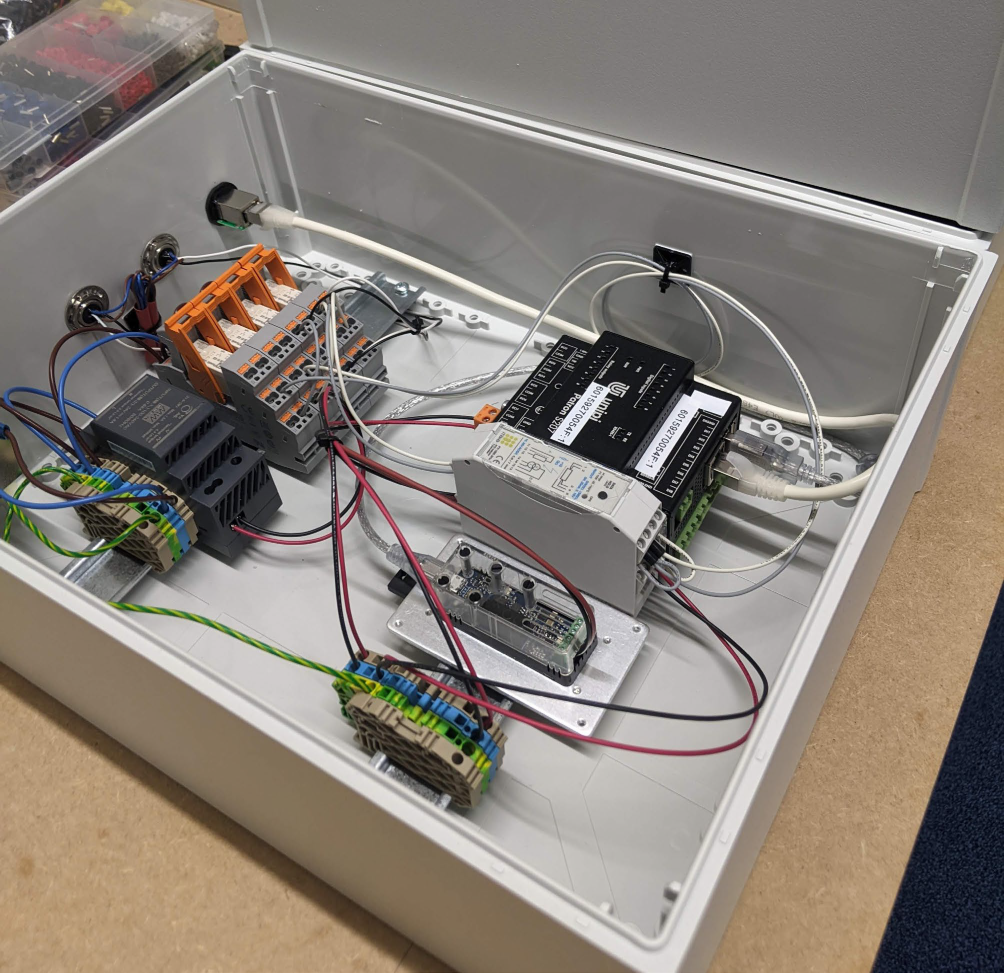

Measuring live filter degradation in HVAC systems is what this project is all about.

Together with Interfilter, a large filter manufacturer, we developed a differential measurement setup to investigate the lifetime of air filters. At the moment most filters are replaced on predefined intervals. But by measuring various parameters in the HVAC installation, premature replacement of filters can be a thing of the past, as filters can be changed when they start underperforming. iotopus’ solution shows real-time power usage, air quality, filter degradation, and more, all in a custom monitoring portal available for the customer.

Used expertise

Back-end development, Front-end development, PCB design, Electronics, Sourcing, Prototype assembly, Sensors, Installation

Digital Twin

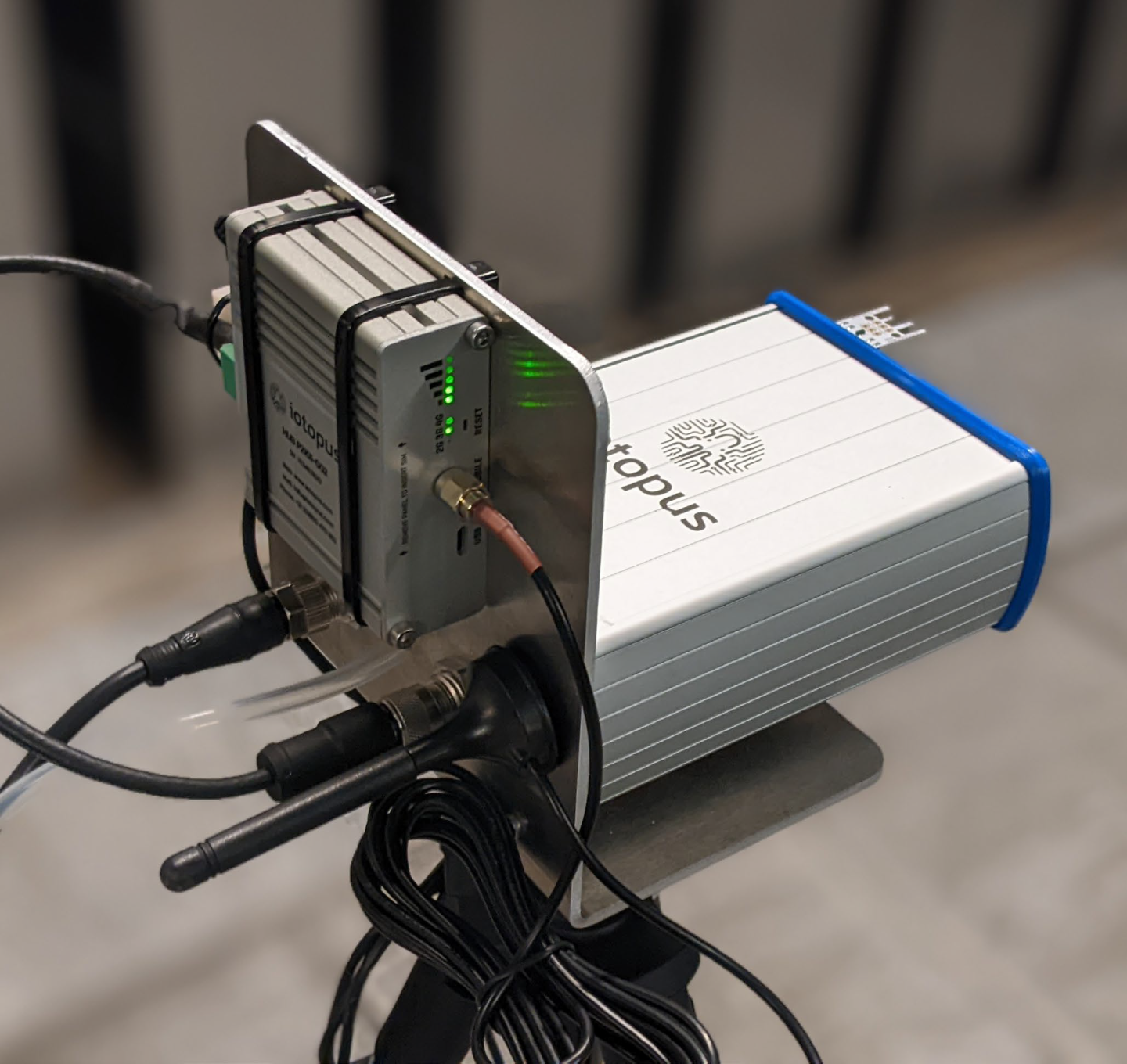

As part of a subsidized project for reducing CO2, iotopus developed the hardware for a “first prototype” setup to harvest and manipulate data from a boiler house in a healthcare institution.

The temperature data from different temperature sensors in the boiler house is “sniffed” by a modular system with smart fallback options. The data is collected by a python scripted 5G Hub, which uploads this to a Digital Twin for further processing. A new set temperature was suggested by the Digital Twin and was “spoofed” into the system to reduce the emissions.

The complete installation of this and testing was executed by

iotopus and commissioned by Sensorfact.

Used expertise

Measurement and Control, Sourcing, Prototype assembly, Electronics, Temperature sensors, Installation